Home > Super Duplex Steel > Super Duplex Steel Forgings

Our company is dedicated to providing a comprehensive selection of Super Duplex Steel Forging, sourced from esteemed vendors recognized for their expertise in manufacturing high-quality super duplex steel. These forgings play a vital role in crafting a wide array of components, offering flexibility in size, grades, and standards to meet diverse customer demands. Highly valued in industries such as oil and gas, marine, and chemical processing, our premium Super Duplex Steel Forging stands out for its exceptional resistance to corrosion and erosion. By incorporating a duplex microstructure, these forgings exhibit superior strength and durability, ensuring uniform mechanical properties throughout the entire forged structure.

| Standard | ASTM A182, ASME SA182 |

| Specification | DIN, ASTM, BS and all International Standards |

| Flat bar blocks | up to 27″ width and 15,000 lbs. |

| Cylinders and sleeves | up to 50″ maximum O.D. and 65″ maximum length |

| Discs and hubs | up to 50″ diameter and 20,000 lbs. |

| Rolled, hand forged or mandrel forged rings | up to 84″ maximum O.D. and 40″ maximum length |

| Rounds, shafts and step shafts | up to 144″ maximum length and 20,000 lbs. |

| Forging Types | Impression Die Forging, Open Die Forging, Seamless Rolled Forging, Hot Forging, Cold Forging, Open die hammer forging, Impression die drop forging, Closed Die Forging, Press Forging, Upset Forging, Compression Forging, Swaging, Rotary Forging, Roll forging. |

| 0.2% Yield Strength, ksi | 65 min |

| Tensile Strength, ksi | 90 min |

| Elongation, % | 25 min |

| Hardness [HRC] | 293 max |

| Element | Cr | Ni | Mn | Si | P | S | C | N | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| MIN | 22.0 | 4.5 | – | – | – | – | – | 0.1 | 3.0 | – |

| MAX | 23.0 | 6.5 | 2.0 | 1.0 | 0.03 | 0.02 | 0.03 | 0.2 | 3.5 | bal |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UAE, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UAE, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Super Duplex Steel Forgings as per DIN, ISO, JIS or ANSI Standard.

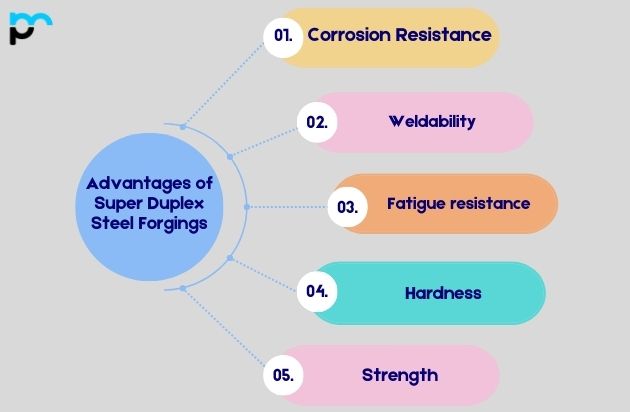

Corrosion Resistance: Super duplex stainless steel forgings exhibit exceptional corrosion resistance, especially in harsh environments containing chlorides, acids and seawater. This strength is superior to that of standard duplex austenitic stainless steels.

Weldability: Super duplex steel forgings are usually weldable using appropriate welding techniques and filler materials. This simplifies design and manufacturing, reducing production and production time.

Fatigue resistance: Due to excellent fatigue resistance, super duplex steel forgings can withstand cyclic loading conditions without failure. This property is useful for pressure vessels, pipelines and structural elements subjected to variable loads.

Hardness: Super duplex steel forgings remain hard even at low temperatures, making them suitable for cryogenic applications. The assets are important in industries such as LNG (liquefied natural gas), transportation, and storage.

Strength: Super duplex steel forgings have superior strength compared to traditional austenite and duplex stainless steel. This makes them suitable for industries that require high levels of mechanical energy, such as those in the offshore and marine environment, chemical manufacturing and oil and gas industries.

Super Duplex Steel Forgings applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil and Gas Industry: Super-duplex steel mesh is widely used in the oil and gas industry for components such as valves, pumps, pipelines, offshore platforms etc. Corrosion resistance, high strength and good weldability in harsh environments make these applications ideal.

Pulp and Paper Industry: In the pulp and paper industry, it is used for digesters, bleachers, washers, pipelines and other equipment due to its resistance to chemical corrosion and high-temperature

Marine Applications: In marine applications, super-duplex steel wings are used in applications such as propeller shafts, submarine pipelines and offshore platforms due to their resistance to corrosion and high mechanical properties

Desalination plants: Super duplex steel grids are preferred in desalination plants for various applications such as pumps, piping and heat exchangers due to their resistance to chloride-induced stress corrosion cracking

Chemical applications: It is also used in chemical applications such as reactors, heat exchangers and storage tanks where corrosion resistance to acids, alkalis and other harmful chemicals is required

Water resistance: Super Duplex steel is known for its excellent corrosion resistance, especially in harsh environments such as marine and chemical applications Determine the level of corrosion resistance required for your application and choose Super Duplex grade accordingly. Typical awards include UNS S32750 (also known as SAF 2507) and UNS S32760.

Cost: Considering the initial cost of materials and any additional costs associated with manufacturing, welding, and maintenance, compare the costs of different super-duplex steels to find the best price. Kari meets the cost and performance needs of your application.

Weldability: Check the weldability of the super duplex steel grade, especially if the forgings will be welded during fabrication or installation. Some grades may require preheat treatment or post-welding to maintain corrosion resistance and mechanical properties.

Temperature and Pressure: Consider the operating temperature and pressure conditions to which the forgings will be subjected. Ensure that the selected super duplex steel grade can withstand these conditions without compromising its integrity.

Mechanical properties: Determine the mechanical properties necessary for your application, including tensile strength, yield strength, and impact resistance. Different types of super duplex steel can have different mechanical properties, so choose the grade that works with your functional requirements.

Super Duplex Steel forgings can be susceptible to galvanic corrosion when in contact with dissimilar metals in certain environments. Proper material selection, insulation, or cathodic protection can mitigate this risk. Monitoring and maintenance are crucial to prevent galvanic corrosion in industrial applications.

Super Duplex Steel forgings are well-suited for hygienic and sanitary applications in industries like food processing, pharmaceuticals, and biotechnology. Their high corrosion resistance, strength, and durability make them ideal for use in environments requiring stringent cleanliness standards, ensuring product quality and safety.

Yes, Super Duplex Steel forgings are recyclable after use. They can be melted down and reused in various applications without losing their mechanical properties or performance characteristics. Recycling Super Duplex Steel helps conserve resources, reduce waste, and lower environmental impact in industrial processes.

Yes, Super Duplex Steel forgings are suitable for underground applications due to their excellent corrosion resistance, high strength, and durability. They withstand harsh underground environments, such as those containing corrosive soils or moisture, making them ideal for pipelines, offshore structures, and underground equipment in various industries.

Call Us: +91 7208967217

Email: sales@pipingmart.ae