Home > Super Duplex Steel > Super Duplex Steel Tubes S32760

Super Duplex Steel Tubes, exemplified by the S32760 grade, stand as stalwarts of durability and corrosion resistance within the stainless steel family. custom-built from a specialized alloy, they boast excellent strength and resilience, making them indispensable across diverse industries. From the demanding realms of oil and gas to the intricate landscapes of chemical processing and marine engineering, these tubes reign supreme. Their exceptional performance under extreme conditions underscores their reliability and longevity, setting a standard of excellence that endures.

| Specifications | : | ASTM A 789 ASME SA 789 |

| Dimensions | : | ASTM, ASME and API |

| Tubes Size | : | 1/8″NB TO 30″NB IN |

| Specialized in | : | Large Diameter Size |

| Schedule | : | SCH20, SCH30, SCH40, STD, SCH80 |

| Type | : | Seamless / ERW / Welded / Fabricated |

| Form | : | Round, Hydraulic Etc |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

| S32750 / S32760 | C | N | P | Si | Mn | Mo | Ni | Cr | S | Other |

| 0.030 | 0.24/0.32 | 0.035 | 0.80 | 1.20 | 3.0/5.0 | 6.00/8.00 | 24.0/26.0 | 0.020 | Cu:0.50 |

| S32750 / S32760 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UAE, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UAE, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Super Duplex Steel Tubes S32750 as per DIN, ISO, JIS or ANSI Standard.

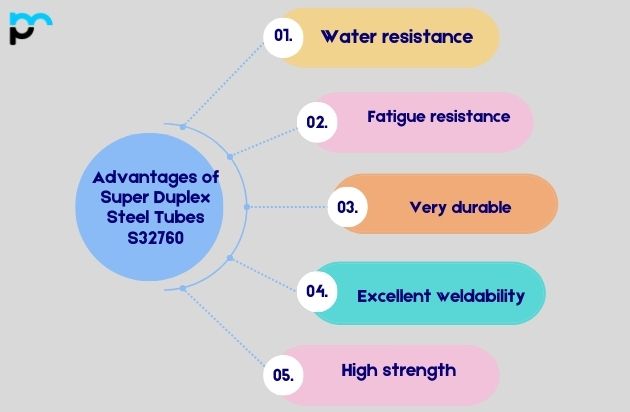

Water resistance: Super duplex steel pipes exhibit excellent corrosion resistance, especially in aggressive environments containing chloride, acid and seawater. This makes them suitable for offshore and marine applications, chemical processing and desalination plants.

Fatigue resistance: These tubes offer high fatigue resistance, making them suitable for cyclic loading applications. This property ensures structural integrity and long-term reliability, especially in dynamic environments such as offshore structures under wave and wind loads.

Very durable: Super duplex steel containers exhibit good strength, even at low temperatures. This property is important for applications in complex environments requiring impact resistance, such as offshore drilling platforms and subsea pipelines.

Excellent weldability: Despite their high strength and corrosion resistance, super duplex steel tubes retain excellent weldability, making them easy to manufacture and install. This makes them desirable for construction projects.

High strength: Super duplex steel vessels have high strength compared to traditional austenite and stainless steel. This results in thinner tube walls and lighter structures without sacrificing functionality, reducing consumption and costs.

Super Duplex Steel Tubes S32760 applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Oil and Gas Industry: Super-duplex steel tubes S32760 are widely used in the oil and gas industry for offshore platforms, subsea pipelines and processing equipment applications. Their corrosion resistance allows them to withstand the harsh conditions of oil and gas exploration and do it to the best of their ability.

Pulp and Paper Industry: In the pulp and paper industry, where corrosive chemicals are used in various stages, these containers are used in digesters, bleachers, washers and other equipment where corrosion resistance is required

Mechanical desalination: Mechanical desalination is becoming increasingly important due to the increasing demand for fresh water. Super duplex steel containers S32760 are used in desalination plants for corrosion resistance in seawater environments.

Chemical processing: These containers are suitable for chemical processing facilities where corrosive chemicals are used. They are also used in heat exchangers, pressure vessels, and reactors where corrosion resistance and temperature rise resistance are required.

Materials: Understand the properties of S32760 Super Duplex steel, including its high strength, corrosion resistance and excellent weldability. Make sure these properties match the requirements of your application.

Pressure and Temperature Considerations: Determine your process’s operating pressure and temperature conditions and select fluids with the appropriate pressure and temperature ratings to ensure proper operation and efficiency.

Size and Design: Consider the required size, outside diameter (OD), wall thickness, and length of the tubs depending on the application and installation.

Compliance with standards: Ensure super duplex steel containers meet applicable standards and specifications such as ASTM, ASME, and NORSOK. Compliance improves pipe quality and reliability.

Corrosion resistance: Check the S32760 tube’s corrosion resistance, especially in harsh environments such as marine, chemical, or oil and gas operations. Ensure adequate corrosion protection is provided.

Yes, Super Duplex Steel Tubes S32760 can be recycled after use. They are highly recyclable due to their composition, consisting primarily of iron, chromium, and nickel. Recycling helps conserve resources, reduce environmental impact, and minimize the need for new raw materials in manufacturing processes.

Yes, Super Duplex Steel Tubes S32760 are suitable for hygienic and sanitary applications. Their high corrosion resistance, strength, and durability make them ideal for use in industries such as food processing, pharmaceuticals, and dairy, where cleanliness and hygiene are paramount requirements for equipment and piping systems.

Yes, Super Duplex Steel Tubes S32760 are suitable for cryogenic applications. Their excellent mechanical properties and resistance to corrosion at low temperatures make them well-suited for use in cryogenic environments, such as liquefied natural gas (LNG) storage and transportation systems, where extreme cold temperatures are encountered.

Yes, Super Duplex Steel Tubes S32760 can be used for underground applications. Their superior corrosion resistance, high strength, and durability make them suitable for underground piping systems in industries such as oil and gas, water distribution, and sewerage, where protection against corrosion and environmental factors is essential.

Call Us: +91 7208967217

Email: sales@pipingmart.ae